Field-Verified. Risk-Informed. Ready for the PHA.

Our Process Safety Experts bring field-savvy insight and deep risk knowledge to your PHA documentation effort. Field verification and updates of Process Safety Information (PSI) require more than a clipboard and a markup—they demand awareness of risk, operational nuance, and the ability to recognize what isn't on the drawing.

Leveraging our expertise in HAZOP, LOPA, and facility safeguarding, our team approaches field verification with the same mindset we bring to high-stakes risk studies—identifying critical safety details, latent design issues, and potential hazard scenarios missed in traditional documentation efforts. Our familiarity with safety systems, interlocks, alarms, and relief systems ensures that the information we collect isn't just accurate—it’s risk-relevant.

As a vendor-neutral provider, our services are fully independent of design firms, control system vendors, or drawing software platforms. There’s no proprietary lock-in or tool dependency—just clear, accurate, and accessible safety documentation. While we often support teams in using this information for PHA and risk analysis, we are not driven by engineering rework or programming upsells.

No agenda—just field-aligned, risk-focused documentation that sets your team up for success.

Unbiased, experienced, and grounded in safety.

PHA FieldSync™ Services

Field-Verified Process Safety Information in you PHA Workshop

PHA FieldSync™ Services from Watchmen Industrial Safety Experts go beyond documentation verification—we bring field reality into focus so your Process Hazard Analysis is built on accurate, current, and risk-aware information.

Why FieldSync™?

Process Safety Information (PSI) forms the foundation of every PHA, but when PSI documents like P&IDs, Cause & Effect diagrams, and PSV data don’t reflect field conditions, your team risks missing critical scenarios.

PHA FieldSync™ Services ensure your safety documentation is not only verified but updated to reflect actual installations—bringing unmatched clarity and precision to your hazard evaluations.

Delivered by Risk Professionals, Not Just Drafters

Unlike traditional field verification services, FieldSync™ is led by seasoned risk and process safety professionals. Our team is trained to:

- Identify latent risk scenarios and design discrepancies that wouldn’t be visible on paper alone

- Recognize field cues such as missing blinds, undocumented spec breaks, or incorrect valve configurations

- Assess alarm and interlock settings, PSV setpoints, and other critical data needed to support robust risk assessments

With this insight, we don’t just confirm data—we strengthen your risk posture.

What We Capture

Our field team collects and harmonizes data across all critical PSI elements, including:

- Alarm and interlock setpoints

- PSV sizing and setpoints

- Spec breaks and car seals

- Restriction orifices, filters, and inline components

- Field-located spec blinds and tagged elements

We also capture 360° field imagery of the unit, equipment, and key hazard areas to embed directly into PHA documentation—providing valuable visual context during team discussions.

Elevate Your View. Expose Hidden Risks.

Drone & Visual Intelligence

We incorporate drone imagery into our PHA Primers to:

- Orient the facilitation team to the layout and configuration of the site

- Provide high-resolution views of elevated areas like tank tops, column nozzles, and access platforms

- Support scenario assessments involving elevation-specific hazards and access limitations

This visual layer makes the PHA smarter, faster, and more grounded in reality.

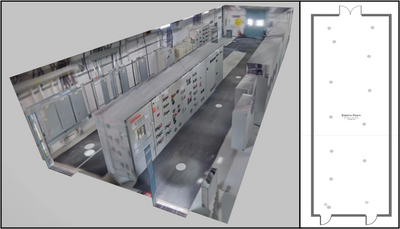

360° Dollhouses: Virtual Access. Real Insight.

Virtual Walkthroughs

Explore process buildings, control rooms, and key hazard zones through a web-based interface. Whether you’re prepping for a PHA or planning a shutdown, the entire team can be visually aligned—no boots required.

Rough Measurement Tools

Need to estimate piping runs, distance to egress, or clearance to a hazard? Our dollhouse models enable approximate material take-offs and distance estimations, making them ideal for planning engineering controls or estimating access risk.

Tagged Safety Features & Critical Equipment

We embed digital markers directly in the model to identify and locate:

- Fire extinguishers and emergency showers

- Emergency exits and muster points

- Gas detectors, vents, and local shutdown buttons

- PSV discharge points and isolation devices

These tags make it easy for teams to identify life-critical assets and understand their proximity to potential hazards or high-risk operations.

Contact us

Whether you're developing a new safety system or improving an existing one, Watchmen delivers independent, vendor-neutral guidance that’s grounded in industry standards, operational reality, and decades of experience.

Partner with us for risk-informed solutions that are accurate, actionable, and aligned with your safety goals.

Join our mailing list

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.